Hi Folks,

Primary drying is longest step of lyophilization process. So, it has to be optimized to make the shortest possible lyophilization recipe for the product.

Till previous posts, we came upto setting the conditions for primary drying step of Lyophilization process.

Once the parameters were set, how long the step of primary drying shall be continued???

The answer is till the frozen ice is removed completely (Some authors describe till removal of unbound moisture) from the formulation.

ok, fine. How we will come to know that there is no ice left in the formulation???

The question need an exact answer. It requires evaluation of quantity of ice in lyophilization chamber.

Now the question is How it can be measured?

For all the above questions, there is multiple answers together called as 'Determination of End point of primary drying".

Here it is.....

The primary drying time is directly related to the ice sublimation rate and is determined by numerous factors, including chamber pressure, shelf temperature, heat transfer coefficient of vials, fill volume, and product resistance.

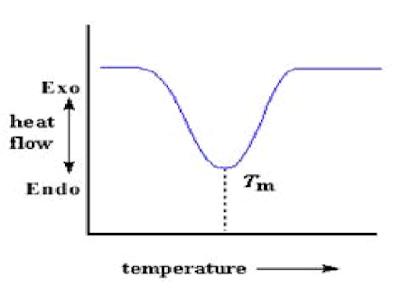

As per the literature, The end point of primary drying can be detected by several different methods. At the end of primary drying, there is no ice present in vials (i.e., no ice sublimation and no heat

removal by sublimation); thus, the product temperature increases to the shelf temperature, and the vapor composition in the freeze-drying chamber changes from essentially all water vapor during primary drying to mostly air or nitrogen. Thus, product temperature data indicate the end point of

primary drying when the product temperature approaches the shelf temperature. Normally, the product temperature as a function of time shows a steep increase in temperature at the end of primary drying, followed by a plateau.

Techniques based on gas composition in the product chamber:

1. Comparative pressure measurement (i.e., Pirani vs.capacitance manometer)

2. Dew point monitor (electronic moisture sensor)

3. Process H2O concentration from tunable diode laser absorption spectroscopy (TDLAS)

4. Lyotrack (gas plasma spectroscopy)

Others:

5. Product thermocouple response

6. Condenser pressure

7. Pressure rise test (manometric temperature measurement (MTM) or variations of this method)

Comparative pressure measurement (i.e., Pirani vs.capacitance manometer):

Comparative pressure

measurement also works well. The thermal conductivity pressure gauge (Pirani pressure gauge) is calibrated against air and shows higher vapor pressure during primary drying because the thermal conductivity of water vapor is about 1.5 times that of air or nitrogen. At the end of primary drying, the pressure difference between the thermal conductivity pressure gauge (Pirani gauge) and capacitance pressure gauge (MKS Baratron gauge, which measures actual pressure) decreases and approaches zero. The point where the Pirani pressure starts to sharply decrease (i.e., onset) indicates that the gas composition is changing from mostly water vapor to nitrogen; i.e., sublimation is “essentially” complete.

Dew point monitor (electronic moisture sensor):

Dew point sensors, which can detect the vapor composition change or the relative humidity in the freeze-drying chamber, shows a sharp dew point decrease at the end of primary drying due to the vapor compositions in the chamber changing from almost 100% water vapor to essentially 100% nitrogen.

Process H2O concentration from tunable diode laser absorption spectroscopy (TDLAS):

Tunable diode laser absorption spectroscopy (TDLAS) directly measures the water vapor concentration (molecules/ cm3) in the duct connecting the chamber and the condenser. The TDLAS unit is commonly installed with two laser beams, one directed with and the other directed against the vapor flow. TDLAS works on basic spectroscopic principles measuring absorption of radiation by water vapor to monitor the trace concentration of water vapor during primary drying that are used to determine the end point of primary drying. The point where water concentration starts decreasing sharply (i.e., onset) indicates that the gas composition is changing, and hence sublimation is

“essentially” complete.

Lyotrack (gas plasma spectroscopy):

This method is the latest addition to the online monitoring devices for freeze-drying and is manufactured by Alcatel Vacuum Technology, France. Lyotrack is based on optical emission spectroscopy and measures water vapor concentration during the drying process.

Product thermocouple response:

The end point of primary drying can also be determined from the product thermocouple response, assuming the vials containing the thermocouples are representative of the batch as a whole. Product temperature approaching the shelf temperature set point is commonly taken as an indication of the end of primary drying.

Condenser pressure:

During primary drying, most of the gas in the chamber is water vapor, and because the total

vapor flux is high, a high ΔP (difference between chamber and condenser pressure) develops to remove the water from the chamber. However, once primary drying is over, ΔP. decreases (i.e., condenser pressure (Pcond) increases since chamber pressure (Pc) is held constant). The condenser

pressure reflects mostly the partial pressure of nitrogen in the condenser. The purpose of the nitrogen bleed is to control the chamber pressure at the desired set point. The point where condenser pressure starts increasing (i.e., onset) indicates that the sublimation is “essentially” over since the high mass transfer portion of the process (i.e., sublimation) is largely over (Fig. 2). A capacitance manometer installed in the condenser reads the condenser pressure.

Pressure rise test (manometric temperature measurement (MTM) or variations of this method):

MTM is a procedure to measure the product temperature during primary drying by quickly isolating the chamber from the condenser for a short time (≈25 s) and analyzing the pressure rise during this period. This analysis yields vapor pressure of ice at the sublimation interface, the product temperature, and the mass transfer resistance of the dried product.

However, the data obtained measure the vapor pressure of ice accurately only as long as the system remains in primary drying. At the end of primary drying, there is little or no pressure rise because all ice is gone, and hence the calculated “vapor pressure of ice” becomes equal to the chamber pressure. Thus, a close approach of the calculated vapor pressure of ice to the chamber pressure forms the basis of the criterion for end of primary drying. The vapor pressure of ice determined by a fit of pressure rise data to the MTM equations approaches the chamber pressure when no ice remains (Refer: X. C. Tang, S. L. Nail, and M. J. Pikal. Freeze drying process optimization by manometric temperature measurement, 2001 AAPS Annual Meeting, Denver, Colorado, 2001).

Thats all about the methods for determination of end point of primary drying.

With regards,

Teja Ponduri

Primary drying is longest step of lyophilization process. So, it has to be optimized to make the shortest possible lyophilization recipe for the product.

Till previous posts, we came upto setting the conditions for primary drying step of Lyophilization process.

Once the parameters were set, how long the step of primary drying shall be continued???

The answer is till the frozen ice is removed completely (Some authors describe till removal of unbound moisture) from the formulation.

ok, fine. How we will come to know that there is no ice left in the formulation???

The question need an exact answer. It requires evaluation of quantity of ice in lyophilization chamber.

Now the question is How it can be measured?

For all the above questions, there is multiple answers together called as 'Determination of End point of primary drying".

Here it is.....

The primary drying time is directly related to the ice sublimation rate and is determined by numerous factors, including chamber pressure, shelf temperature, heat transfer coefficient of vials, fill volume, and product resistance.

As per the literature, The end point of primary drying can be detected by several different methods. At the end of primary drying, there is no ice present in vials (i.e., no ice sublimation and no heat

removal by sublimation); thus, the product temperature increases to the shelf temperature, and the vapor composition in the freeze-drying chamber changes from essentially all water vapor during primary drying to mostly air or nitrogen. Thus, product temperature data indicate the end point of

primary drying when the product temperature approaches the shelf temperature. Normally, the product temperature as a function of time shows a steep increase in temperature at the end of primary drying, followed by a plateau.

Techniques based on gas composition in the product chamber:

1. Comparative pressure measurement (i.e., Pirani vs.capacitance manometer)

2. Dew point monitor (electronic moisture sensor)

3. Process H2O concentration from tunable diode laser absorption spectroscopy (TDLAS)

4. Lyotrack (gas plasma spectroscopy)

Others:

5. Product thermocouple response

6. Condenser pressure

7. Pressure rise test (manometric temperature measurement (MTM) or variations of this method)

Comparative pressure measurement (i.e., Pirani vs.capacitance manometer):

Comparative pressure

measurement also works well. The thermal conductivity pressure gauge (Pirani pressure gauge) is calibrated against air and shows higher vapor pressure during primary drying because the thermal conductivity of water vapor is about 1.5 times that of air or nitrogen. At the end of primary drying, the pressure difference between the thermal conductivity pressure gauge (Pirani gauge) and capacitance pressure gauge (MKS Baratron gauge, which measures actual pressure) decreases and approaches zero. The point where the Pirani pressure starts to sharply decrease (i.e., onset) indicates that the gas composition is changing from mostly water vapor to nitrogen; i.e., sublimation is “essentially” complete.

Dew point monitor (electronic moisture sensor):

Dew point sensors, which can detect the vapor composition change or the relative humidity in the freeze-drying chamber, shows a sharp dew point decrease at the end of primary drying due to the vapor compositions in the chamber changing from almost 100% water vapor to essentially 100% nitrogen.

Process H2O concentration from tunable diode laser absorption spectroscopy (TDLAS):

Tunable diode laser absorption spectroscopy (TDLAS) directly measures the water vapor concentration (molecules/ cm3) in the duct connecting the chamber and the condenser. The TDLAS unit is commonly installed with two laser beams, one directed with and the other directed against the vapor flow. TDLAS works on basic spectroscopic principles measuring absorption of radiation by water vapor to monitor the trace concentration of water vapor during primary drying that are used to determine the end point of primary drying. The point where water concentration starts decreasing sharply (i.e., onset) indicates that the gas composition is changing, and hence sublimation is

“essentially” complete.

Lyotrack (gas plasma spectroscopy):

This method is the latest addition to the online monitoring devices for freeze-drying and is manufactured by Alcatel Vacuum Technology, France. Lyotrack is based on optical emission spectroscopy and measures water vapor concentration during the drying process.

Product thermocouple response:

The end point of primary drying can also be determined from the product thermocouple response, assuming the vials containing the thermocouples are representative of the batch as a whole. Product temperature approaching the shelf temperature set point is commonly taken as an indication of the end of primary drying.

Condenser pressure:

During primary drying, most of the gas in the chamber is water vapor, and because the total

vapor flux is high, a high ΔP (difference between chamber and condenser pressure) develops to remove the water from the chamber. However, once primary drying is over, ΔP. decreases (i.e., condenser pressure (Pcond) increases since chamber pressure (Pc) is held constant). The condenser

pressure reflects mostly the partial pressure of nitrogen in the condenser. The purpose of the nitrogen bleed is to control the chamber pressure at the desired set point. The point where condenser pressure starts increasing (i.e., onset) indicates that the sublimation is “essentially” over since the high mass transfer portion of the process (i.e., sublimation) is largely over (Fig. 2). A capacitance manometer installed in the condenser reads the condenser pressure.

Pressure rise test (manometric temperature measurement (MTM) or variations of this method):

MTM is a procedure to measure the product temperature during primary drying by quickly isolating the chamber from the condenser for a short time (≈25 s) and analyzing the pressure rise during this period. This analysis yields vapor pressure of ice at the sublimation interface, the product temperature, and the mass transfer resistance of the dried product.

However, the data obtained measure the vapor pressure of ice accurately only as long as the system remains in primary drying. At the end of primary drying, there is little or no pressure rise because all ice is gone, and hence the calculated “vapor pressure of ice” becomes equal to the chamber pressure. Thus, a close approach of the calculated vapor pressure of ice to the chamber pressure forms the basis of the criterion for end of primary drying. The vapor pressure of ice determined by a fit of pressure rise data to the MTM equations approaches the chamber pressure when no ice remains (Refer: X. C. Tang, S. L. Nail, and M. J. Pikal. Freeze drying process optimization by manometric temperature measurement, 2001 AAPS Annual Meeting, Denver, Colorado, 2001).

Thats all about the methods for determination of end point of primary drying.

With regards,

Teja Ponduri