Hi Pharma folks,

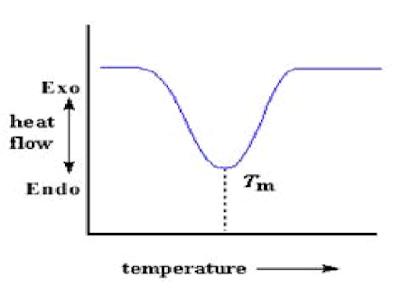

A Sample done with DSC, the result tells us, what is the thermal event , is it a glass transition, is it eutectic melt, and what are the critical temperatures that are associated with it. Glass transition doesn’t mean that’s going to collapse the sample.Sometimes we may have a glass transition that occurs, and we see no collapse. So this is the beauty of using both the microscope and the DSC, in that the microscope complements and supports the data that we get from the DSC.

In Freeze dry microscopy tells us where that sample physically loses structure.

What actually happens in Freeze dry microscopy?

The sample upon exposure to heat during DSC, may undergoes various thermal events. But, we cannot view/visualize those events. There comes Freeze dry microscopy (FDM). With FDM, we can view the various thermal events of sample directly with change in temperature as well as pressure combination. Nothing but, we can simulate the conditions of Freeze drying at micro level and see what happens to the sample.

In FDM, very tiny sample quantity (typically Less than 2 µL) will be placed on thermally controllable stage and completely enclosed in a chamber in order to hold the vacuum applied. (just imagine a lyophilizer chamber with shelves). The sample will be undergone cooling and followed by applying vacuum and further increasing the temperature at a slow phase to see at what temperature the collapse of the sample is visible.

FDM is nothing but, a direct examination of stages of freeze drying using a special microscope and a thermal stage (Thermally controllable stage as mentioned in above paragraph).

What a Freeze dry microscope contains?

Sample Preparation:

The bulk solution which has to be lyophilized should be the sample for Freeze dry microscopy. The sample which has to be lyophilized should be utilized in FDM. Below diagram depicts the sample preparation at a glance.

Now, let us know about parts of a stage.

The sample stage is provided with a vacuum ports, and for stage adjustment purpose will have X and Y manipulators visible on exterior view and also a sample holder will be present inside which will be place onto the stage with the help of sample door lock.

Coming to the interior of stage, a 22 mm silver block containing 1.3 m light aperture onto which the sample will be placed, and is connected with below parts as provided in the picture.

Before sample loading, below procedure shall be followed.

A Sample done with DSC, the result tells us, what is the thermal event , is it a glass transition, is it eutectic melt, and what are the critical temperatures that are associated with it. Glass transition doesn’t mean that’s going to collapse the sample.Sometimes we may have a glass transition that occurs, and we see no collapse. So this is the beauty of using both the microscope and the DSC, in that the microscope complements and supports the data that we get from the DSC.

In Freeze dry microscopy tells us where that sample physically loses structure.

What actually happens in Freeze dry microscopy?

The sample upon exposure to heat during DSC, may undergoes various thermal events. But, we cannot view/visualize those events. There comes Freeze dry microscopy (FDM). With FDM, we can view the various thermal events of sample directly with change in temperature as well as pressure combination. Nothing but, we can simulate the conditions of Freeze drying at micro level and see what happens to the sample.

In FDM, very tiny sample quantity (typically Less than 2 µL) will be placed on thermally controllable stage and completely enclosed in a chamber in order to hold the vacuum applied. (just imagine a lyophilizer chamber with shelves). The sample will be undergone cooling and followed by applying vacuum and further increasing the temperature at a slow phase to see at what temperature the collapse of the sample is visible.

FDM is nothing but, a direct examination of stages of freeze drying using a special microscope and a thermal stage (Thermally controllable stage as mentioned in above paragraph).

What a Freeze dry microscope contains?

Sample Preparation:

The bulk solution which has to be lyophilized should be the sample for Freeze dry microscopy. The sample which has to be lyophilized should be utilized in FDM. Below diagram depicts the sample preparation at a glance.

Initially, the sample stage will be like this.

Now, let us know about parts of a stage.

The sample stage is provided with a vacuum ports, and for stage adjustment purpose will have X and Y manipulators visible on exterior view and also a sample holder will be present inside which will be place onto the stage with the help of sample door lock.

Coming to the interior of stage, a 22 mm silver block containing 1.3 m light aperture onto which the sample will be placed, and is connected with below parts as provided in the picture.

- Liquid nitrogen inlet

- Liquid nitrogen outlet

- Thermocouple leads (for temperature determination)

Before sample loading, below procedure shall be followed.

- Ensure silver block is cleaned and have enough silicone oil on the aperture.

- Place a 16 mm cover slip and a sample separator and then 2 µL bulk solution followed by 13 mm cover slip.

Operation:

- Initially the Freeze dry microscope should be calibrated with known concentration of calibrating substance such as NaCl.

- Once, the collapse temperature was attained within a specified range, then actual sample shall be evaluated.

- The sample will be ran through the steps of freezing similar to lyophilization recipe but at a faster rates during freezing.

- Once sample was frozen completely, then focus has to be adjusted such that sample was clearly visible clearly.

- Then vacuum pump was switched on and slightly temperature was increased to start primary drying at a rate that all the thermal events are clearly recorded.

- If any rough idea about the range of the transition temperature then at that temperature, drying at a slow rate shall be performed.

- The images will be captured such that at material changes at all temperature points with each 0.1°C for accurate recording of collapse.

- Once collapse is identified, it can be taken a screenshot and video/images can be recorded.

- Then the sample shall be brought back to room temperature and vacuum pump to be swithced off, and vacuum to be made to atmospheric pressure.

- Stage shall be cleaned and closed with the lid.

- The example FDM data is provided below which helps to interpret the data.

Note:

Why colors ?

When we use a Ist order red compensator, depending on the material whether Isotropic or an-isotropic in presence of polarized light, the images obtained are colored as per the orientation of ice crystals frozen direction (IF ice crystal formed parallel to the direction of light path will show one color and if in perpendicular to light path then other color).

For complete concept please refer (Practical Application of FD Microscopy in Product Thermal Characterization, by Ruben Nieblas).

Thats all for the FDM, will post on primary drying concept in the next post.

Till then, take care.

Yours,

Teja Ponduri